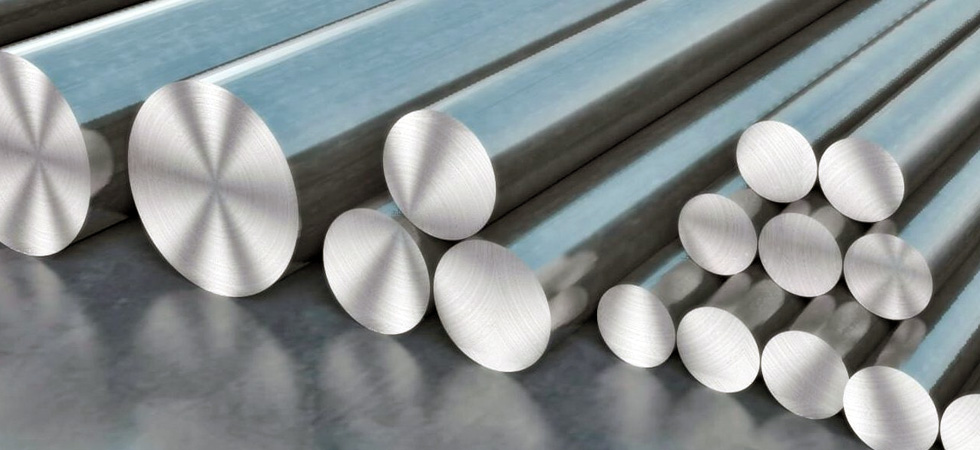

Bright Bars

Stainless Steel Bright Bars Manufacturer, SS Bright Bars Supplier, Cold Drawn Bright Bars Exporter, Peeled Bright Bars Stockist, Bright Round Bars, Bright Hex Bars, Bright Square Bars, Hot Rolled Bright Bars, Bright Steel Bars Supplier in India.

Overview

Bhansali Precision is a recognized manufacturer, supplier and exporter of Bright Bars. We manufacture bright bars with high quality raw materials and are tested by our quality control inspectors before delivering to our customers worldwide. We manufacture bright bars in compliance with national & international standards like ASTM, AMS, DIN, BS, En, IS, JIS, etc. These bright bars are available in a wide range of sizes, grades, shapes like round, hex, square and specifications.

Our bright bars are demanded by our customers across the globe due to high quality, best price and delivery on time. Our bright bars are corrosion resistant, durable and have excellent strength.

Our bright bars are used in many industries and applications like automotive industry, telecom sector, oil & gas industry, engineering industry, defense sector, mining industry, pump shafts, machined components, machine tools, surgical and medical parts, threaded bars, valves, fasteners, etc.

For any requirement of Bright Bars, Contact us today for best prices

Product Specifications

| Materials: | Specialized in Stainless Steel - 303, 304L, 316L, 410, 431, 430F, 416; Duplex, Alloy Steel & Free Cutting Steel, Nickel Alloys, Inconel, Monel, Hastelloy, Aluminium, Copper, Brass |

|---|---|

| Standard | DIN, BS, EN, IS, ASTM, AMS, JIS & Other International Standards. |

| Size | from 2.00mm to 6.35mm (0.078″ to 0.25″) dia |

| Thickness | 5 mm To 500 mm thick in 100 mm TO 6000 mm |

| Finish | Bright, Black, Polish |

| Form | Round, Square, Hex (A/F), Bush, Rectangle, Flat, Wire Mesh |

| Condition | Cold Drawn & Polished, Cold Drawn, Centreless Ground & Polished |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Processing | Bar cutting to 650mm |

Cold Drawn Bright Bars Condition

| H&T | Hardened and tempered. |

| ANN | Annealed |

| PH | Precipitation hardened |

Drawn Bright Bars

Round Bars

Peeled Bright Bars

Drawn Bright Bars

| Condition | Cold Drawn & Polished | Cold Drawn, Centreless Ground & Polished | Cold Drawn, Centreless Ground & Polished (Strain Hardened) |

| Grades | 201, 202, 303, 304, 304L, 310, 316, 316L, 321, 410, 420, 416, 430, 431, 430F, 430F DIN & others | 304, 304L, 316, 316L, 321, 4140, 410 | |

| Diameter (Size) | 2 mm to 5mm (1/8" to 3/16") | 6mm to 22m (1/4" to 7/8") | 10mm to 40mm (3/8" to 1-1/2") |

| Diameter Tolerance | h9 (Din 671),h11 ASTM A 484 | h9 (Din 671) ASTM A 484 |

h9 (Din 671),h11 ASTM A 484 |

| Length | 3/4/5.6/6 meter (12/14ft/20feet) |

3/4/5.6/6 meter (12/14ft/20feet) | 3/4/5.6/6 meter (12/14ft/20feet) |

| Length Tolerance | -0/+200mm or +100mm or +50mm (-0 ”/+1 feet or +4 ” or 2 ”) |

-0/+200mm or +100mm or +50mm (-0 ”/+1 feet or +4 ” or 2 ”) |

-0/+200mm (-0 ”/+1 feet) |

Peeled Bright Bars

| Condition | Peeled, Centreless Ground & Polished | Peeled & Polished | Peeled (Rough Turned) |

Forged, Rough Turned |

| Grades | 201, 202, 303, 304, 304L, 310, 316, 316L, 321, 410, 420, 416, 430, 431, 430F, 430F DIN, 1.4418, 1.4462, Duplex (2205) & others | 304, 304L, 316, 316L, 410, 416, 420, 431, 17-4 PH (2205) | 303, 304, 304L, 316, 316L, 410, 416, 420, 431 | |

| Diameter (Size) | 20mm to 85mm (3/4 ” to 3--1/4 ”) | 85mm to 140mm (3-1/4 ” to 4--3/4 ”) | 25mm to 140mm (1 ” to 5--1/2 ”) | 150mm to 400mm (6 ” to 16 ”) |

| Diameter Tolerance | h9 (Din 671) ASTM A 484 | h11 |

K12/K13 (Din 1013) | -0mm/+3mm (-0 ”/+0.12 ”) |

| Length | 3/4/5.6/6 meter (12/14ft/20feet) |

3/4/5.6/6 meter (12/14ft/20feet) | 3/4/5.6/6 meter (12/14ft/20feet) | 3 meter -5 meter 10 feet -16 feet |

| Length Tolerance | -0/+200mm or +100mm or +50mm (-0 ”/+1 feet or +4 ” or 2 ”) |

-0/+200mm or +100mm or +50mm (-0 ”/+1 feet or +4 ” or 2 ”) | -0/+1000mm or 500mm (-0 ”/+3 feet or +2 feet) | -0/+2 meter- -0/+6 feet |

Application Industry

Aerospace

Automobile

Bracket

Distillery

Electrical Appliance Hardware

Electronic Hardware

Frame Structures

Heaters

Railway Engineering

Motors

Pumps